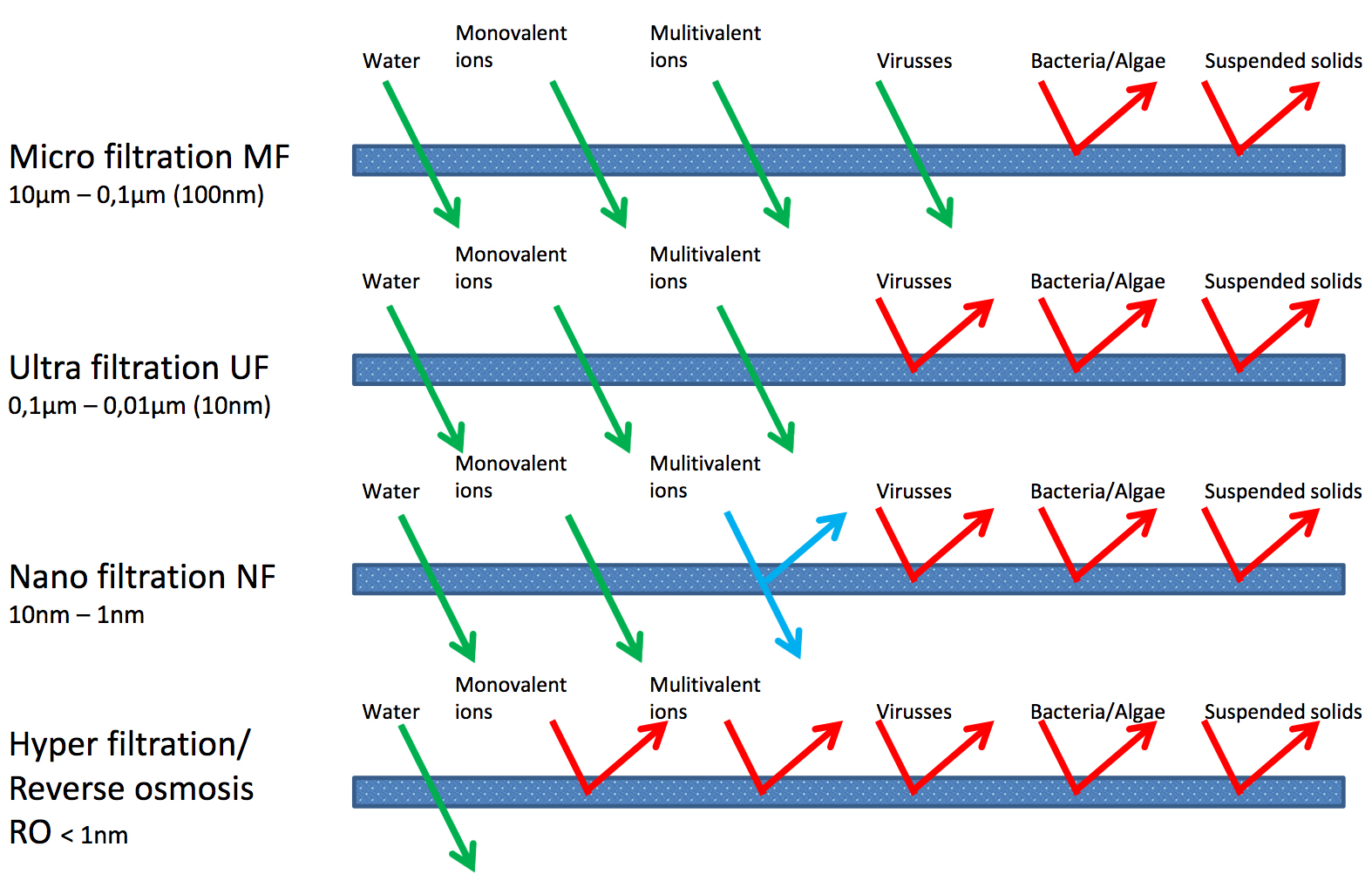

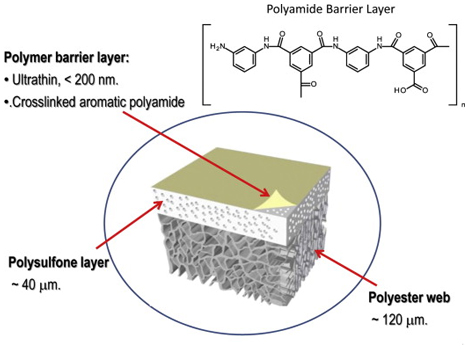

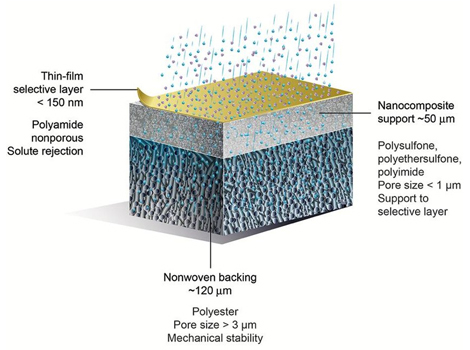

The membranes is basically made up of 3 thin layers of Polyamide layer at the top, Polysulfone layer at the middle and finally polyester layer at the bottom. Polyamide layer is 0.2 µm, polysulfone layer is 40 µm and polyester layer is 120 µm. The three layer configuration gives the preferred properties of high elimination of undesired materials (like salts), high filtration rate, and good mechanical strength. Depending on the pore size, membranes can be classified as Micro Filtration (MF), Ultra Filtration (UF), Nano Filtration (NF) and reverse osmosis (RO) membranes. Membranes can also be of various thicknesses, with homogeneous or heterogeneous structure. Membranes can be neutral or charged, and particle transport can be active or passive. The concluding can be facilitated by pressure, concentration, chemical or electrical gradients of the membranes process.

Technology

Layers Of Membranes

Osmotech produced Flat Sheet Membranes advantages.

- Excellent chemical resistance, thermal characteristics, Surface treatments.

- Superior quality product performance

- Enhance capacity

- Less investment, operational and manual cost reduction.

- Consume less time

- Boost business

Types of Membranes Technology

(our Products):

- RO (Reverse Osmosis)

- Residential Membrane

- NF (Nano Filtration)

- MF (Micro Filtration)

| PARAMETER | NANO FILTRATION | MICRO FILTRATION | REVERSE OSMOSIS | ULTRA FILTRATION |

|---|---|---|---|---|

| Separation principle | Size, charge, similarity | Size | Size, charge, similarity | Size, charge |

| Size of species separated(Um) | ~0.001 | 0.1-20 | <0.001 | 0.001-0.1 |

| Typical separated species | Sugars, pesticides | Silts, bacteria, cysts, spores | Salts, sugars | Proteins, viruses, end toxins, pyroxenes |

| Typical recovery (%) | 50-95 | 90-99.99 | 30-90 | 80-98 |

| Cross Flow velocity (ms-1) | 0.1-0.5 | 1-3 | 0.1-0.25 | 0.2-1 |